Our PVC Plastic Shrink Bands provide an extra level of tamper-evident security, as well as preserving product freshness when applied around the neck of any plastic or glass container. Shrink bands are one time use only. And cannot be reused after initial removal. This is ideal, as a broken shrink band is an IMMEDIATE indicator that the integrity of a bottle has been tampered with. A tightly sealed, and unbroken shrink band is a universally recognized indication of product security and freshness.

We carry shrink bands in a variety of sizes, colors, prints, and styles. Such as Flat-Cut, Roll Stock, and Preforms. Most shrink bands are typically made from clear, high quality PVC plastic sheet material. Our flat-cut and preformed shrink bands are available in bundles, sleeves or by the case. Shrink bands are also commonly referred to as custom bands, tamper-evident bands, tamper-evident seals, safety seals, cap bands, cap seals, and seamless bands.

Flat-Cut Shrink Bands - Simple in concept, and easy to use. Flat-cut shrink bands are available with or without horizontal or vertical perforations. And are produced in large rolls of plastic tubing that are then cut to industry-standard lengths. And are sold by the bundle or by the case. Flat-cut shrink bands can be specially ordered custom-cut to exact customer specifications. Or... if you prefer. Just buy a whole bulk roll, and cut your own lengths.

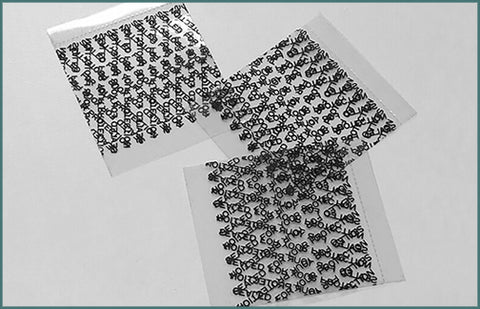

Printed Shrink Bands - Are designed primarily as a reaffirmation to your customer of security and product freshness. Often printed with assuring phrases like "Sealed for your protection" or "Tamper evident seal". They can be ordered with custom artwork if desired.

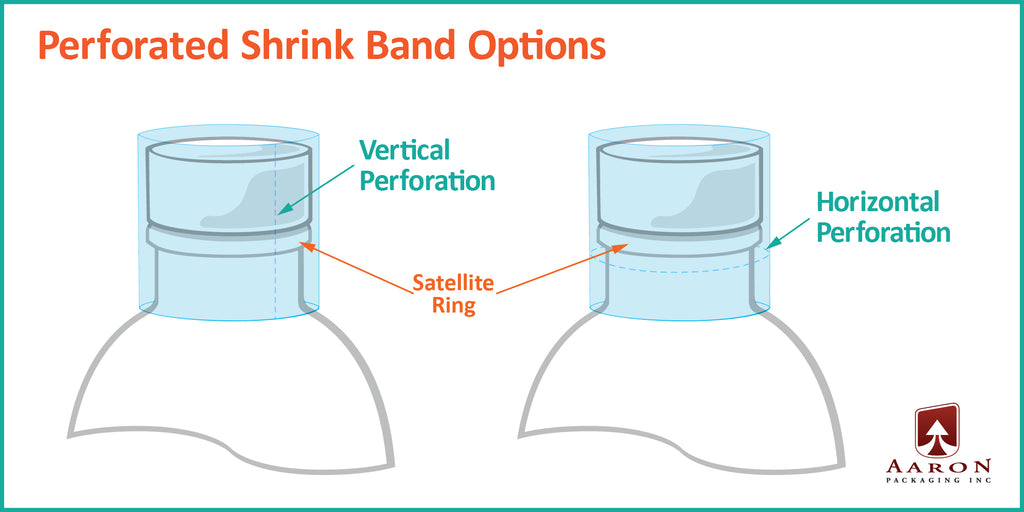

Perforated Shrink Bands - Have a line of small holes stamped through the plastic film. Forming an easy to tear area. There are two distinct shrink band perforation styles.

Vertical Perforation - The perforation line runs vertically from the top to the bottom of one side of the shrink tube. The shrink band must be broken apart along that perforation line to be able to twist off the cap.

Horizontal Perforation - The perforation line runs horizontally along the diameter of the shrink band. Usually just under the bottom of the lid or cap. Typically, the perforated line is used to allow the customer to twist the cap off the container along with the upper part of the perforated shrink band.

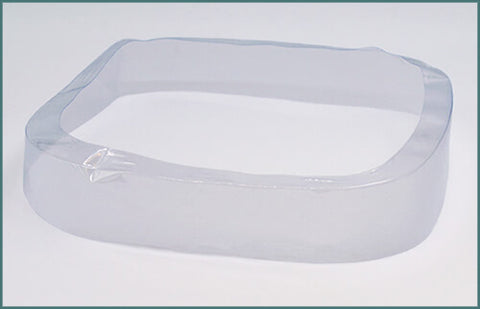

Preform Shrink Bands - Shrink bands that have been pre-shaped to fit specific sized and shaped, (even square-shaped) containers. These shrink bands are easy to use as well. Just drop the preformed band down over your container lid, and apply heat to shrink and seal. Our preform bands are available without, or with vertical perforations.

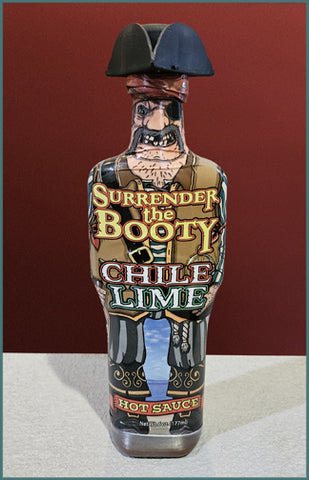

Custom Shrink Sleeves - Are designed to cover the entire container, including the neck. In addition to ensuring tamper-evident security and preserving product freshness, shrink sleeves serve an additional purpose in providing a printable display surface over the entire container. Allowing for unlimited options in customizing the branding and design of the product packaging. This option is a simple, and relatively inexpensive way to make a product stand out as unique amongst many others on a display shelf.

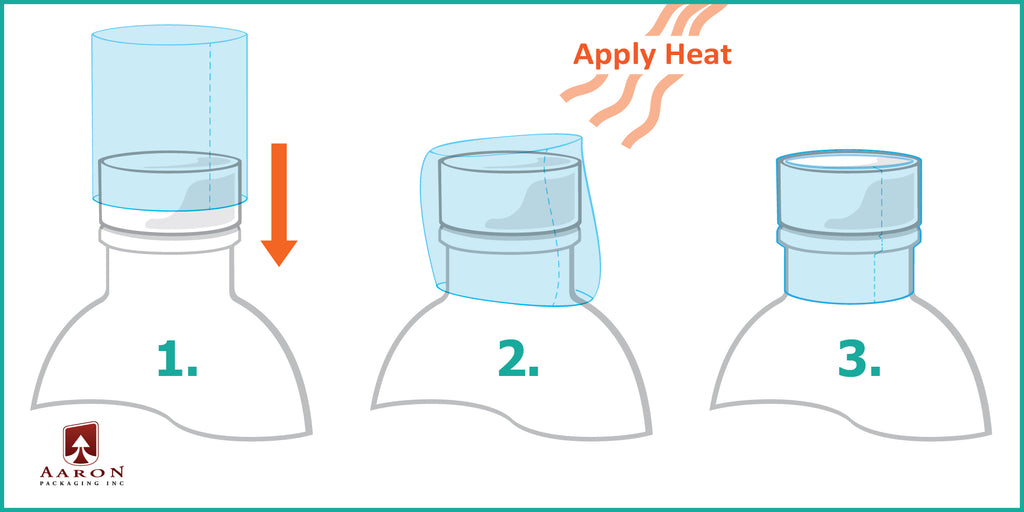

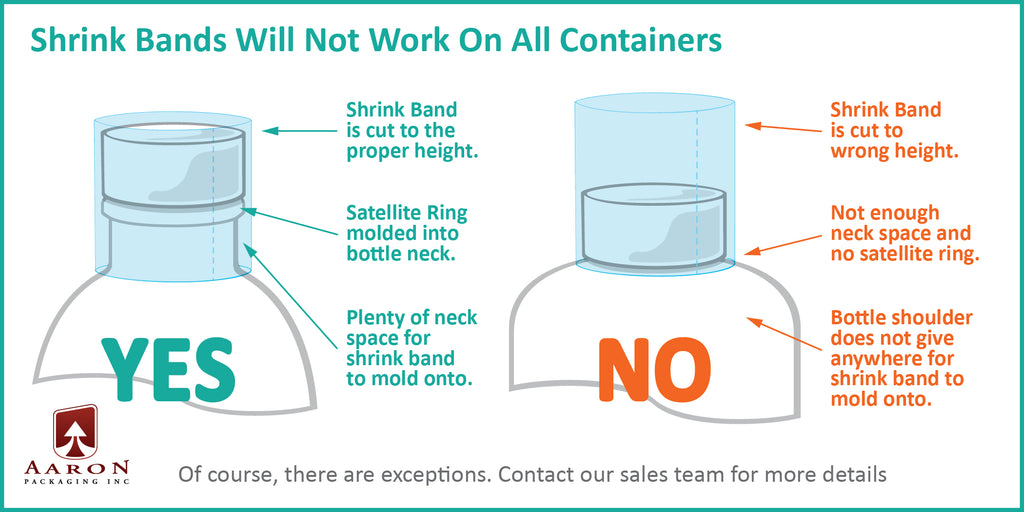

How To Apply - All of our shrink bands are applied via the application of heat. Thereby "shrinking' the plastic till it firmly molds itself around the cap and neck of your product. Place the shrink band down over the bottle neck till about half the band covers the bottle neck. And the other half covers the cap. It's important that the band fully encloses over the bottle satellite ring. To create a tamper-evident seal, it's important that the shrink band covers BOTH the cap and the container neck. Many containers are specifically designed to accept shrink bands. Such containers have what is called a "satellite" ring molded into the plastic or glass neck of the container. One of the purposes of a satellite ring is to act as an "anchor" for the shrink band.

Use a heat gun to shrink the plastic film around the cap and bottle neck. It's best to move the heat gun nozzle about in a pattern to ensure that the shrink band receives an even, overall application of heat. Continue moving the nozzle evenly around the shrink band till the plastic film has molded itself completely to the shape of the bottle neck and cap. In the case of a shrink sleeve, you will place the sleeve down over the entire container.

Applying heat to mass quantities of bottles is best done by passing the bottles and shrink bands through a heat tunnel machine. If you think you may need such a machine, please contact our sales team.

When NOT To Use Shrink Bands - Although exceptionally versatile, shrink bands are not compatible with every container or cap style. Such as containers with little to no neck space for the shrink band to solidly mold to. Containers like Boston Round and Cylinder bottles are examples of bottle designs that may not work. Flip-top, lotion disc-top caps and pumps or sprayer caps are also not ideal for shrink band use. Generally, we list the shrink bands that are compatible with our containers and caps in the "add on" section of each product page.

Have more questions? - If you would like more information. Or you wish to create your own personalized shrink bands or shrink sleeves for your product containers. Please contact our customer service team